At the beginning of the year, a contract signed with Danish manufacturer EnerDry A/S for the manufacture and installation of two sugar pulp drying equipment developed by EnerDry in a sugar production plant in the United Kingdom came into force.

In 2022, the Estonian service division of Axioma servisas installed such equipment in France.

The project will run until mid-2026

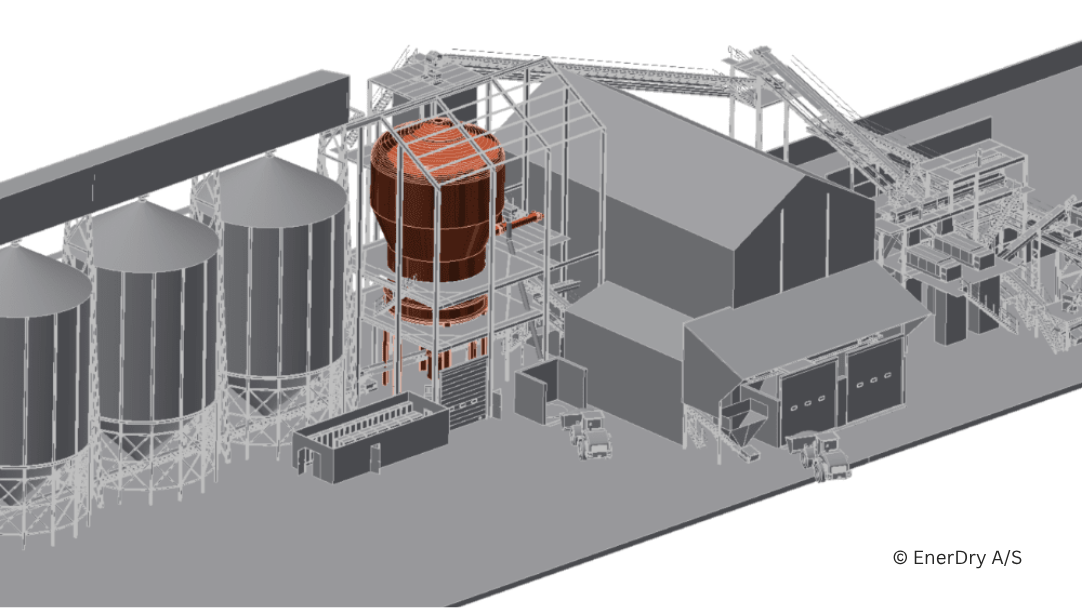

Two giant EnerDry units will be installed on the site of the sugar factory, one of which is almost 22 meters high and weighs up to 350 tones. The design and ordering of the necessary components is currently underway. Actual installation work is expected to start in the autumn of this year.

The sugar beet pulp drying plant will be installed in three phases. First, the individual units will be manufactured from steel structures. Once the production is complete, these structures will be assembled to ensure that the exact dimensions match the customer’s drawings. After inspection, the units will be dismantled and prepared for transport. The gigantic structures will be transported by sea and land to the United Kingdom Sugar factory site. Once the structures arrive, assembly of the plant units will begin. This will be followed by the installation of the internal equipment.

“We have already carried out a similar project, so we do not foresee any major challenges. The only challenge is to familiarize ourselves with the laws and regulations in the UK, as we have not yet carried out projects in this country,” says Darius Imbrasas, Head of the Estonian service division.

Danish technology

EnerDry device is much more sophisticated than conventional sugar beet pulp drying devices. The technology developed by Danish engineers allows the water vapour released during the process to be cleaned and reused.

The drying process uses high pressure steam. This is transferred to a heat exchanger, which generates the heat that dries the sugar beet cake. The hot air stream is stirred using a fan.

Sugar beet cake is used as animal feed, soil conditioner, etc. Recently, some companies have been experimenting with the use of this bagasse in the production of paper or bio-packaging.

About the client

EnerDry is a Danish company founded in 1998, whose steam drying technology has been awarded and recognized worldwide. EnerDry engineers have developed a plant that can also be used for drying wood chips, grain residues, sludge, fibrous material and brown coal.