Measuring instruments and systems are an integral part of industrial processes. In energy, water, manufacturing and other industries, a wide range of parameters are monitored, affecting not only the quality of products but also the efficiency of processes. Thermal imagers are one of the most widely used instruments in industry. Their advantages and applications will be discussed in this article.

Temperature is important in most processes

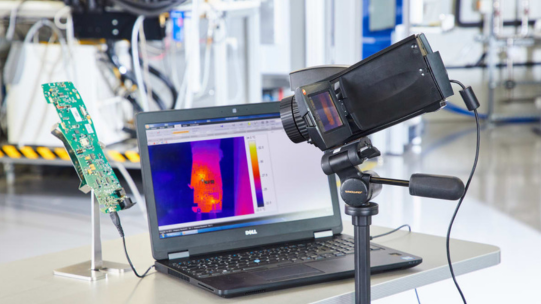

Thermal imagers are devices that measure and display the temperature of objects in the infrared spectrum. They can detect and visualize heat differences between different surfaces or objects. This allows you to see where temperature changes are greatest or where equipment failures could occur.

It is difficult to find a process for which temperature is completely irrelevant. In many of them, specialists need to know exactly what it is and how far it has deviated. For this reason, thermal imaging can be used in a wide range of industrial applications, building maintenance, warfare, hunting, etc.

Equipment maintenance and diagnostics

Thermal imaging cameras can easily detect potential faults or malfunctions in industrial equipment. The detection of thermal differentials is important in electrical, automation, mechanical and heating and cooling equipment or systems.

In equipment, heat buildup is caused by increased friction between mechanical components such as bearings, gears or conveyor belts, by faulty electrical contacts, or by the spread of corrosion between connecting parts, etc.

In production process supervision

Thermal imaging cameras are used to monitor production processes, helping to optimize them and ensure the highest quality of products.

These measuring devices help to identify energy losses and inefficient production lines and to check the quality of the products produced.

In building maintenance

The most popular and well-known application for thermal imaging is building maintenance.

They can be used to detect deficiencies in the thermal insulation of buildings, to assess the overall thermal performance of buildings, to assess the heat loss of individual zones, and to detect construction defects and mould.

Environmental and occupational safety

Thermal imaging cameras can be used to detect hot or potentially hazardous areas that may affect occupational safety or environmental protection.

In occupational safety, they can detect hot spots on surfaces or faults in equipment that may pose a risk to workers, and in environmental protection, they can detect unusual heat sources, such as fires or heat emissions from industrial plants, that have a negative impact on the environment.

Thermal imagers are useful instruments for monitoring equipment and production processes, energy, environmental protection, occupational safety and building maintenance. In industrial plants, they can detect problems early, save time and money, and ensure a safe and efficient working environment.

Axioma servisas represents the professional German manufacturer Testo thermal imaging cameras, which can be used in all of the above mentioned applications. If you are interested in more detailed information about these measuring devices, please contact the responsible specialist of our company by phone +370 686 97791 or by e-mail orders@axs.eu.