At the beginning of the heating season, the annual biofuel-testing boom is taking place in the accredited Axioma Servisas laboratory. During the cold season, more than 100 standardised solid biomass fuel tests are performed daily in this laboratory.

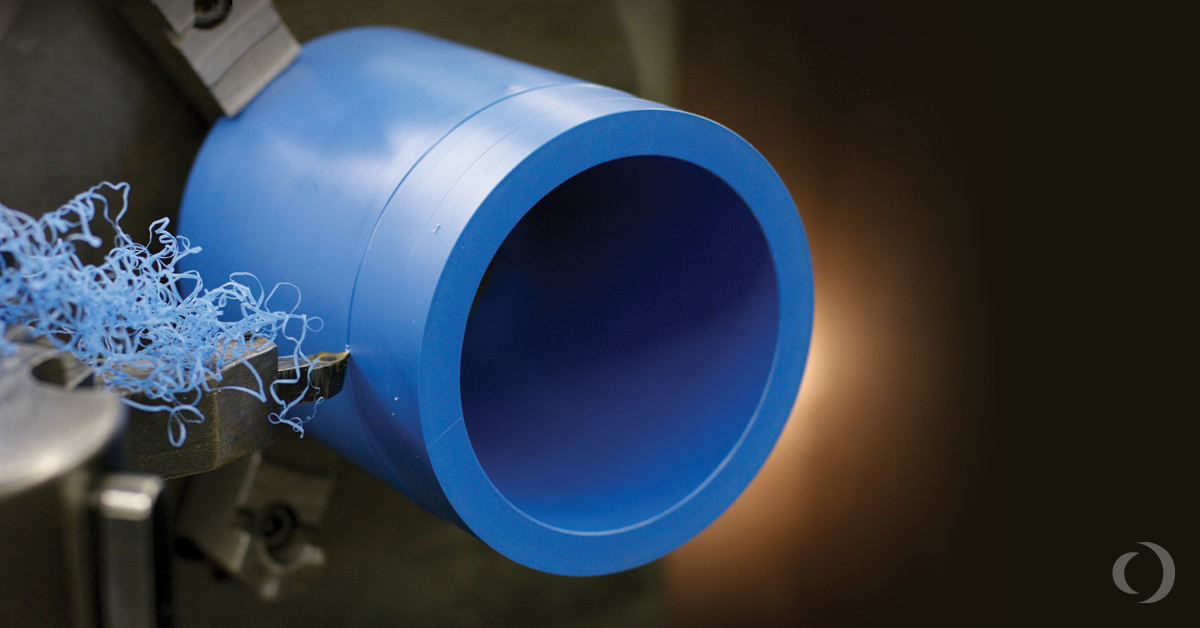

Various types of biofuel can be tested at the laboratory located in Vilnius: deforestation waste, peat mixed with biofuel, pellets and briquettes. Tests of grain shells and straw are sometimes ordered, while some of the most interesting samples studied so far are reeds from the Žuvintas Biosphere Reserve and coffee grounds compressed into pellets, which were used as biofuel.

“Most of the time we test deforestation waste, and come across clean and beautiful biofuels quite rarely, only that coming from sawmills,” said Ilona Senavaitienė, the Head of the Biofuel Research Laboratory.

The laboratory already counts more than 60 contractual customers. These regular customers receive many more added benefits than those commissioning individual researches. One of the benefits is access to the information system allowing monitoring the results of the tests in real time, to see all the data of previous tests and even to label the samples with a BAR code to ensure confidentiality. In addition, Axioma Servisas takes samples from customers and, if necessary, they can be collected regularly, according to a pre-arranged schedule.

Loyal customers also enjoy other advantages: monthly payments, more flexible prices and supply of special packaging. It is important to emphasise, that by entering into a contract the customers are not obliged to send samples – even when testing is not requested for several months, they do not have to pay any subscription fee.

Biofuel laboratory of Axioma Servisas features modern multilingual information system Biolab, which allows fast and accurate data transfer, ensuring their confidentiality and avoiding human errors. One of the most unique advantages of this system is its compatibility with KEMEK weighbridge data processing program used at most boiler plants, which can scan test data and automatically calculate tonnes of oil equivalent (TOE), thus saving the time required for accounting.

It is estimated that more than 10 tons of biofuel will be tested in the laboratory during this year’s heating season, and the total number of tests will exceed 350,000 units.

“The laboratory is capable of performing as much as 360 humidity tests, 62 ash content and calorific value tests each and 10 granulometry tests per day, thus, we still have the plenty of resources and plan to use it in the future,” said the Head of the Biofuel Research Laboratory.