Axioma Servisas, a company providing the widest range of maintenance services to the industrial sector in Lithuania, continues expanding the list of represented equipment suppliers – this time the company has become a representative of Alfa Laval products and an official service partner in Lithuania. Founded in Sweden more than 100 years ago, the company manufactures pumps, boilers, heat exchangers, industrial fittings and other products for the cleaning, refining and reuse of materials, thus promoting a more responsible use of natural resources.

As many as 16,700 Alfa Laval employees develop innovative technologies that have a significant impact on increasing energy efficiency and heat recovery, optimising water treatment processes and reducing emissions. The equipment developed and manufactured by Alfa Laval is used by leading companies in the fields of energy, marine and food processing and water treatment all around the world.

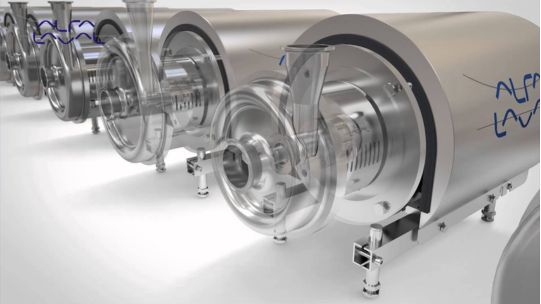

Pumps – for hygienic processes

The Alfa Laval brand is best known on the market for its industrial pumps. Their wide range offers the selection all the most popular types of pumps – centrifugal, reciprocating, vacuum and twin- or triple-screw.

Alfa Laval pumps meet the highest EHEDG and 3-A SSI hygiene standards and are therefore used in dairy, food, beverage, biotechnology and pharmaceutical companies where equipment is subject to extremely strict requirements.

The products are characterised by convenient and simple maintenance, as the front loading structure allows easy replacement of seals, filters and other maintenance work.

Heat exchangers – for customers with exceptional requirements

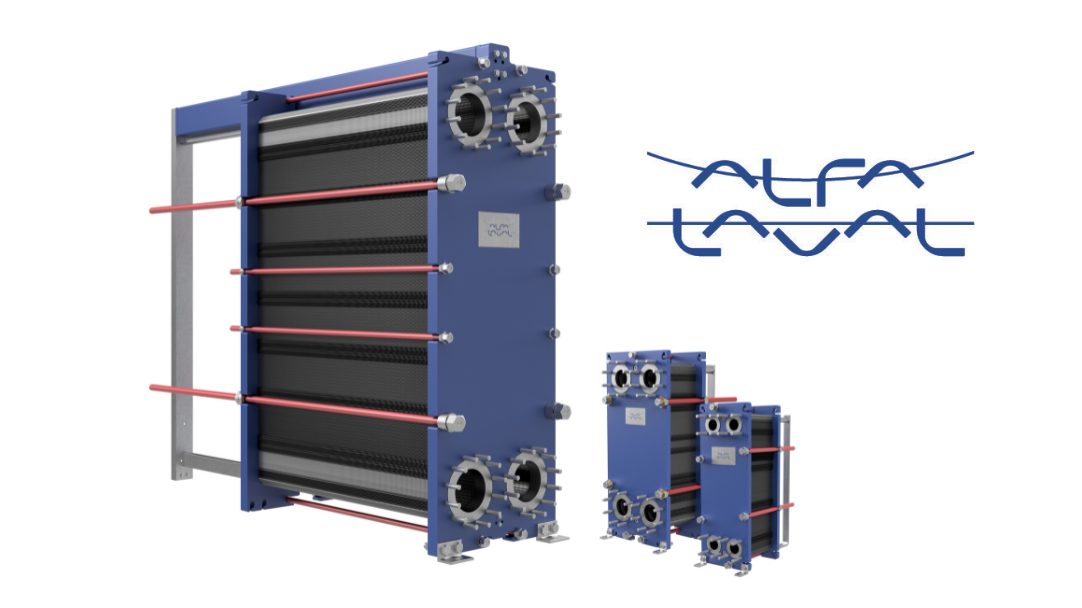

The manufacturer also offers equipment for heat transfer from one medium to another – plate and tubular heat exchangers.

Alfa Laval produces three types of plate heat exchangers – prefabricated, fusion-bonded and welded. Prefabricated plate heat exchangers are characterised by compactness, fusion-bonded are used in aggressive media or processes where high hygiene standards are important, and welded – at high temperature and pressure.

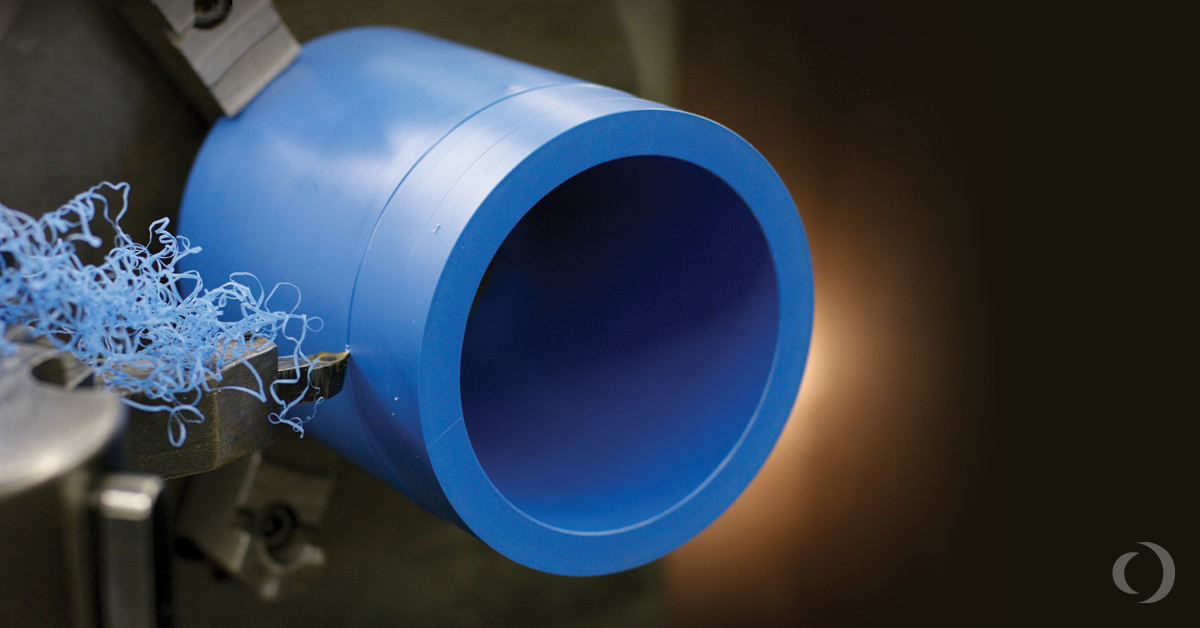

Another heat exchanger found in the industry is the one with a scraped (scratched) surface. It is intended for viscous, heat-sensitive, crystallised or sticky products.

Alfa Laval is the only manufacturer that offers not only single but also double-wall scraped-surface heat exchangers to the market. Their unique rotary scraping technology removes contaminated materials throughout the operation cycles, making these heat exchangers ideal for processing sensitive solid particles.

Heat exchangers with a scraped surface are used to preserve the main aspects of taste and quality, and plate heat exchangers are used in energy, water management, pharmaceutical and other industrial fields.

Industrial fittings – for convenient process management

Alfa Laval also manufactures valves and dampers that meet the specific needs of customers in the dairy, food, beverage and pharmaceutical industries. Simple management, hygiene and economy are the main features of industrial fittings produced in Sweden.

Control and safety valves as well as quarter-turn, knife-gate and butterfly valves for various production lines that require automated control help to reduce water, cleaning agent and energy consumption.

Official representative in Lithuania – Axioma Servisas

Axioma Servisas has become the official representative and authorised service partner of Alfa Laval products in Lithuania. If you are interested in the supply of this manufacturer’s products or repair services, contact our specialists who will help you find the best solutions and promptly update the equipment you are using.