Yet another company made a decision to install automatic pH measurement and calibration system of KNICK manufacturer represented by Axioma Servisas, which helps ensure consistent control and monitoring of pH indicators.

In sugar production, pH stability and accuracy are important factors, and even minor deviations can have a tremendous impact on the quality of the final product. The use of the smart system of the German manufacturer KNICK will ensure automatic calibration and repeated daily cleaning of electrode in the company, while everything will be performed without human interference.

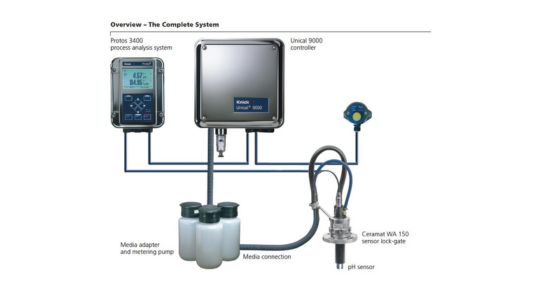

It is a unique unparalleled system in the market. It is easy to assemble, it looks clean and simple, and does its job really well. The system comprises pneumatic reinforcement for inserting an electrode into the process, digital Memosens electrode, electro-pneumatic controller and a secondary device that is the brain of the entire system (displaying the process parameters, errors and electrode status, and transmitting all the data to the client’s SCADA system in real time).

Without KNICK Unical 9000, the electrode calibration and replacement are usually a rather complex process. The production process must be rerouted or the production has to be completely stopped because after unscrewing the electrode, the liquid would pass through its connection due to the pressure and flow. Calibration and replacement of the electrode is usually carried out in rather hazardous conditions: high ambient temperature and humidity. The electrode is washed with acid, which is a slow procedure that requires caution and concentration. KNICK Unical 9000 system calibrates the electrode every morning and cleans it several times a day without human involvement.

Axioma Servisas is an authorised KNICK representative in the Baltic States and offers high-quality innovative products to clients operating in niche areas of activity.