Industry, heat supply, utilities, biofuel and other sectors emit a lot of heat that can be converted into electricity. One of the most effective ways to accomplish this is with the help of ORC, or Organic Rankine Cycle technology. Its application in the French brand ENOGIA equipment allows to extract energy from industrial waste or heat emitted in the process of biomass combustion.

ORC technology and device operation

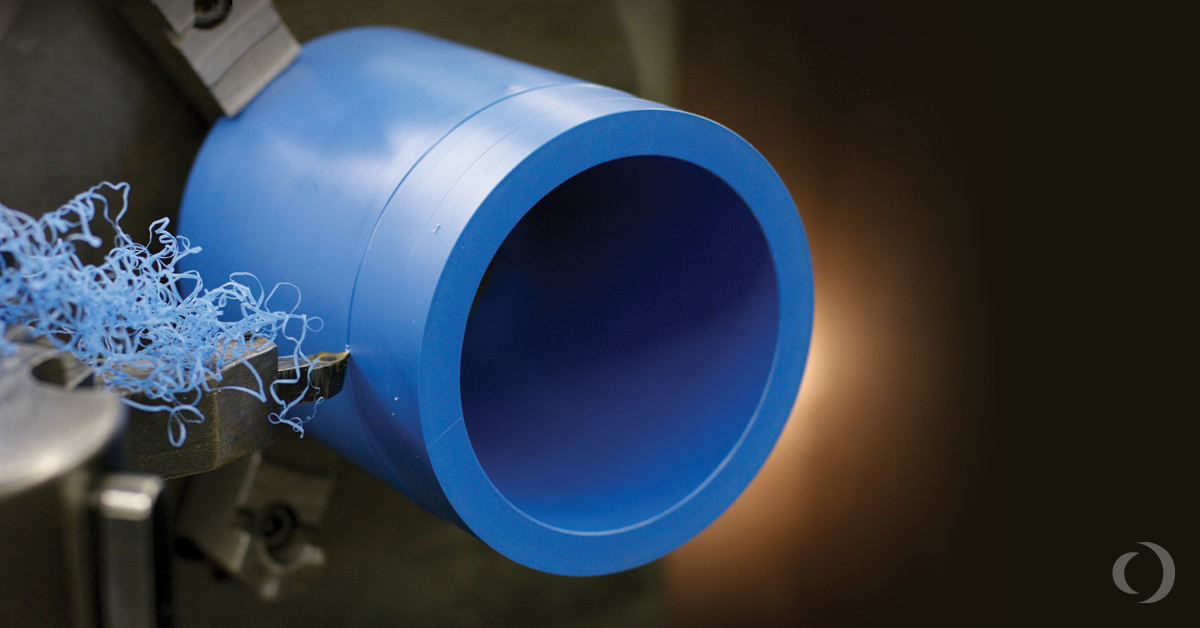

The Organic Rankine Cycle (ORC), named after the Scottish mechanical engineer W. J. M. Rankine, was invented and tested back in the 19th century. Today, ORC equipment is some of the most innovative ways to convert heat into electricity. They are similar to traditional steam turbines, but use high molecular mass organic liquid vapour instead of water vapour. Therefore, a lower operating temperature of 70 to 120oC is sufficient for such equipment.

When using an organic liquid, no condensation occurs in the ORC turbine after vapour expansion. Therefore, the surfaces of the blades are not affected by erosion, which ensures their longevity (30-40 years without special maintenance). The high reliability of not only the turbine but also the entire system is due to the fact that the latter is not penetrated by air. A special high-temperature resistant grease, i.e., a heat agent, circulates in the combustion chamber. This kind of system ensures safety, smooth and fully automated operation of the steam generator.

Relevance of ORC technology today

The ORC equipment generates electricity using heat from renewable sources such as geothermal and solar energy, biomass, biogas or even waste. This allows businesses to reduce costs, while electricity generated from surplus heat can be used locally or returned to the network, even generating extra profit.

The ORC turbine can operate for 24 hours per day, 7 days a week, subject to the availability of a heat source. Such devices are the smallest in terms of power (production capacity from 10 to 180 kW) and the most compact.The parameters of the ORC devices designed and manufactured by ENOGIAare adjusted to take into account the specific characteristics of each application. Therefore, they can be applied in a variety of industries and energy fields. The unique design of the devices ensures intuitive operation, maintenance and service.

Possibilities of using ORC devices

ORC devices are particularly successful in the industrial and energy sectors. They are also useful in shipping, where electricity can be generated using heat from propulsion or auxiliary engines. ORC equipment allows to improve the efficiency of generators (diesel, natural gas, biogas) by additionally producing electricity from used heat (exhaust gas, cooling water). They are often applied in the geothermal energy sector, as well as in solar farms.

Axioma Servisas UAB is the representative of ENOGIA in Lithuania. It is one of the first in the country to offer ORC equipment. The company provides all related services: design, supply, installation, management and maintenance. Specialists with extensive experience in energy projects are ready to introduce the new product to the market that allows efficient production of electricity from renewable heat sources. Contact us if you are considering this option.