“Axioma servisas”, the industry’s largest service provider, adds another one to its basket. From autumn, the company’s specialists will not only supply gas analysers from advanced manufacturers, but also carry out metrological verification. The accredited laboratory team will test single-channel and multi-channel gas leakage analysers, and certificates will be issued to those that meet the requirements.

Inspection is mandatory every 6 months

In accordance with the procedures laid down by the Metrology Law of the Republic of Lithuania, all explosive or toxic gas analysers used on the premises of companies must undergo a timely metrological inspection. This means that the instruments must be checked in accordance with a specific procedure that assesses the compliance of the metrological parameters of the measuring instruments with the established requirements.

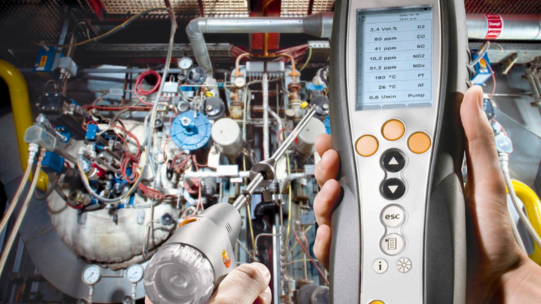

The “Axioma servisas” laboratory will offer a metrological verification service for gas leak analysers-signals from autumn this year. Experts with more than 20 years of experience will be able to check the measuring instruments at the customer’s site or by delivering the gas leak analysers to the laboratory in Vilnius. Once they have been metrologically verified, the company’s specialists will issue a certificate and a verification mark, which will be affixed to the measuring instrument that meets the requirements.

Metrological checks must be carried out every 6 months, and failure to produce valid documents after an inspection by the authorities authorised by the Government of the Republic of Lithuania could result in a financial penalty of up to €10,000.

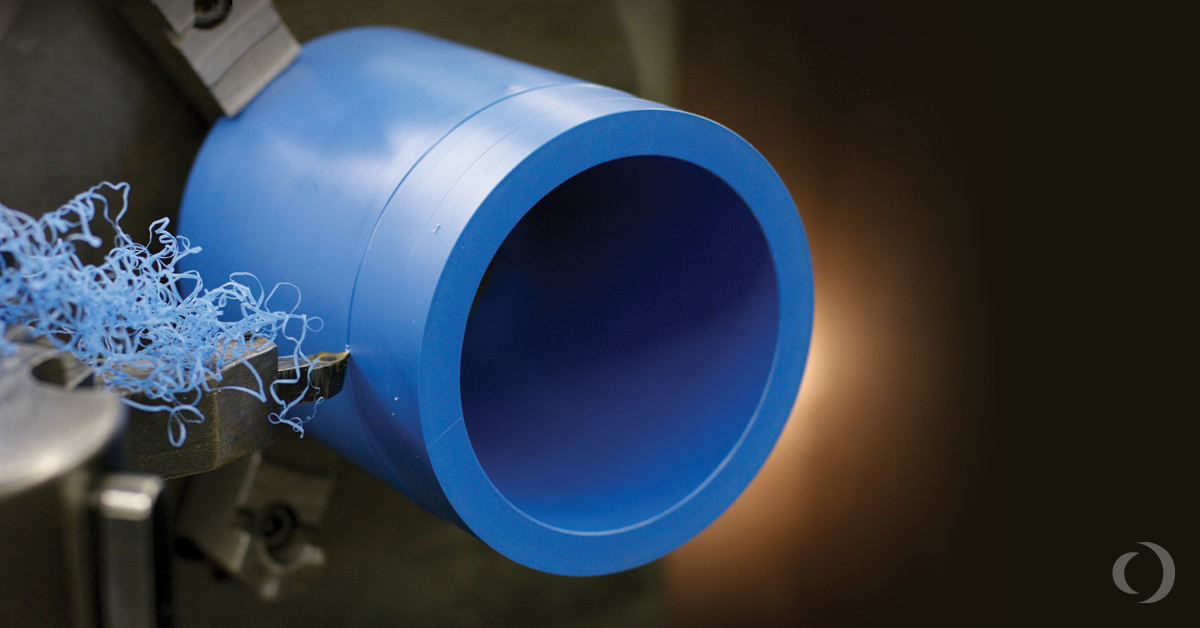

Used in most industrial plants

Gas leak detectors are indispensable in all metalworking, food and chemical industries, boiler houses, underground sites and logistics centres. Here, carbon dioxide, nitrogen monoxide, hydrocarbon and other gases are emitted and must be monitored continuously. This is done in accordance with the laws in force in the Republic of Lithuania and to protect workers and premises from accidents.

For example, the smoke emitted from boiler houses contains fine particles of carbon monoxide. If the amount exceeds the legal limit, workers can be poisoned. In some cases, there may even be a risk of explosion. To eliminate these risks, analysers-signals are installed in the rooms to continuously monitor the level of hazardous gases in the environment and report any deviations.

“Our customers are companies that are required to use gas analysers on their premises. When supplying them, we have found that metrological verification of the measuring devices is of particular importance. So we have engaged this service so that the customer receives both the gas analysers and their regular checks from our company,” says Eglė Nugaraitė – Juršienė, Laboratory Manager at “Axioma servisas”.

More information about the service is available here.