The Biofuel Research Laboratory, which has recently moved to new premises in Vilnius, Zietelos g. 3, is successfully developing its activities, expanding its customer base not only in Lithuania, but also abroad, and plans to offer new services to customers.

An audit by the National Accreditation Bureau has confirmed that the new premises comply with the LTS EN ISO/IEC 17025:2005 standard. The audit was positive and the laboratory is able to continue its activities in the accredited field, and intensive work is continuing.

Customer base is expanding

The Biofuels Testing Laboratory currently has around 70 contracts in force and the same number of customers. According to Ilona Laugalytė, Technical Manager of the Biofuel Research Laboratory, up to 6 new contracts have been signed every month on average recently. The customer profile is also changing: whereas previously the laboratory’s customers were mainly heat producers (boiler houses), nowadays a significant part of the customer base consists of fuel suppliers themselves.

“There is now a strong conviction in the biofuels market that testing fuel quality is not only mandatory but also beneficial. However, for a long time it was the responsibility of the heat producers themselves. Now, Lithuanian fuel suppliers are beginning to understand the trends and nuances of the biofuel market, and are beginning to develop and adopt the existing culture of the biofuel market. Thus, they are no longer passive observers of the market, just selling fuel and waiting for results and payment, but are actively participating in it themselves. It becomes in the interest of the suppliers to know the quality and value of the fuel they are supplying to the facilities, rather than waiting for the heat producer to assess its quality,” said I. Laugalytė.

Setting foot in foreign countries

The technical manager of the laboratory is pleased that the Lithuanian biofuel culture is slowly spreading to neighbouring countries. Currently, the laboratory has already signed contracts with Latvian companies.

“Our laboratory is already working with the first Latvian biofuel samples. We hope that this important expansion process will continue and that we will be able to welcome the next heating season with an increased list of “foreign” clients,” said I. Laugalytė.

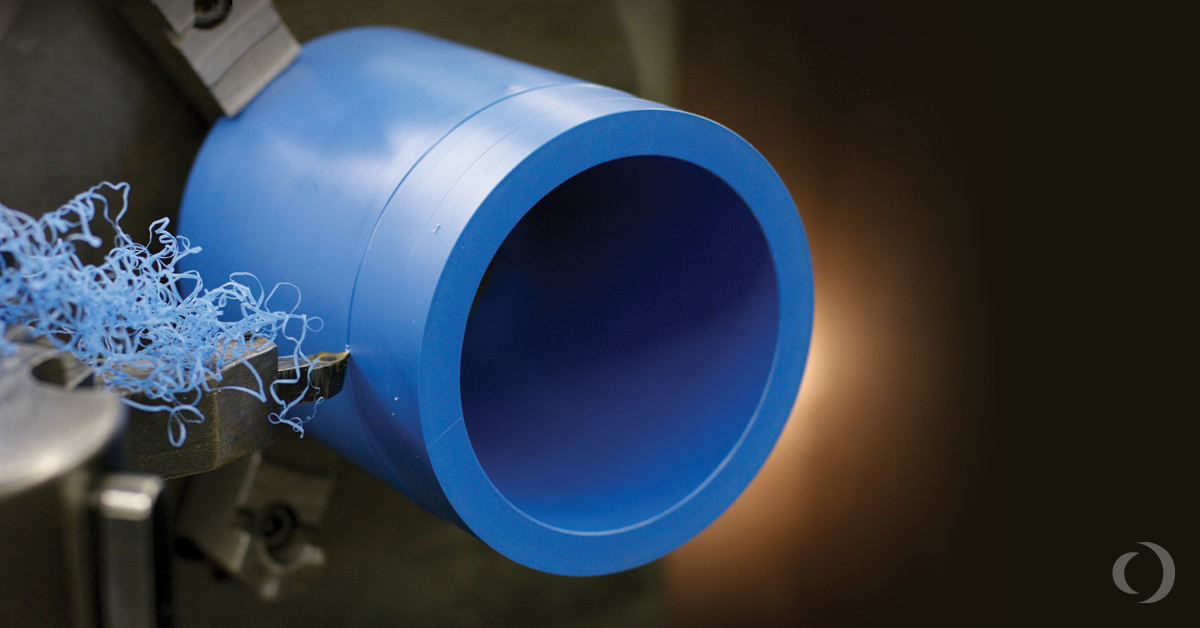

Granulometry is on the cards

When asked about the plans to expand the basket of services, Ms Laugalytė mentioned that the plans include the provision of granulometry services. The purpose of this study is to find out the size distribution of fuel particles, in other words, to find out how many and what size fuel particles are present in a sample.

“In our daily practice, we see that very often the basic fuel indicators (moisture content, ash content and calorific value) do not reflect the true quality of the fuel. This is where studies on the size distribution of biofuel particles can be of great help. Even very good quality fuels may contain a large number of fine particles (e.g. sawdust) which compromise the combustion quality, leading to a reduction in the efficiency of the boiler and even to a fire risk. Therefore, in addition to the basic quality indicators of biofuels, it is very useful to know the particle size of the fuel, because if you buy a few tonnes of sawdust or peat, the basic quality indicators will show a very good quality fuel, but if these tonnes are fed into the boiler, it can cause serious problems. This is why the fuel is usually non-homogeneous, i.e. mixed (chips, bark, spines, some sawdust), as this is the way to obtain the optimum combustion quality,” explained the technical manager of the laboratory, explaining the importance of quality tests.