Many technological and industrial processes are unthinkable without pumps – the devices that move liquids, gases, mixtures and other materials from one environment to another. Depending on the type, model and characteristics of the pumps, they can be used in water management, agriculture, energy, oil refining, food industry, HVAC systems, etc. Below we discuss the most popular types of pumps and their applications.

Centrifugal pumps are the most widely used

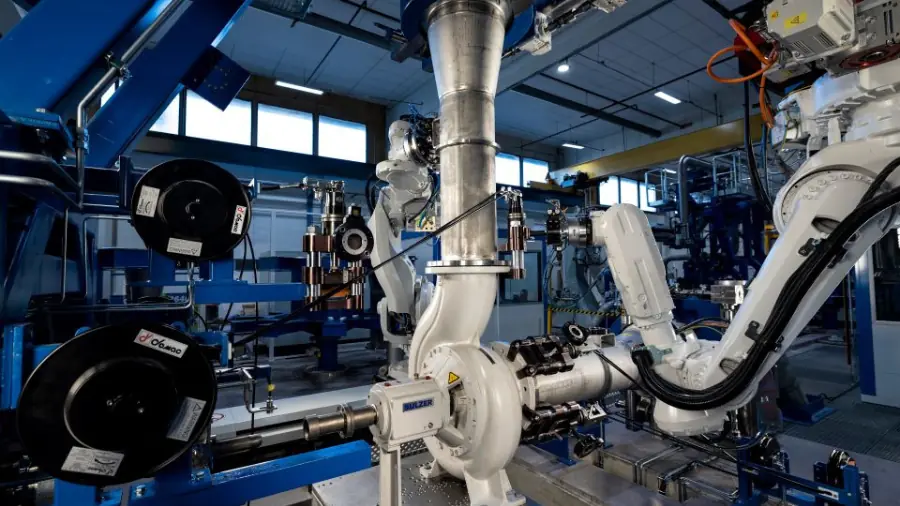

Centrifugal pumps are the most common pumps used in practice and their main task is to pump liquids. They can be used with water as well as with chemically aggressive, corrosive, corrosive, viscous, abrasive and explosive liquids. Centrifugal pumps are used in a wide range of applications and environments, such as wastewater systems, the dairy industry, paint and varnish production, acid and alkali dosing in pH control processes.

The centrifugal pump category includes single-stage, multistage, self-priming and double inlet industrial pumps. Each has different applications. For example, vertical multistage centrifugal pumps are installed in factories, industrial process or water and other fluid supply systems where a single-stage centrifugal pump is not capable of delivering extremely high liquid pressures.

Double inlet or split case industrial pumps can only handle clean or chemically non-hazardous liquids and are used in applications such as boilers and cooling towers. These pumps are extremely easy to service – just unscrew the pump top and inspect the impeller and shaft, and dismantle and replace them if necessary.

Circulation pumps – for HVAC systems

Professional circulators are designed for heating, air conditioning and ventilation systems. These types of pumps are installed indoors to protect them from possible atmospheric influences.

The area, type and pipe diameter of HVAC systems are the main criteria for selecting the capacity of a circulator. Thinner pipes require a more powerful circulator, while thicker pipes require a less powerful circulator.

Dosing pumps – for extremely precise liquid delivery

Dosing pumps are piston-type pumps that pump the liquid precisely at a set rate. One of the biggest advantages is that the pumping rate can be adjusted by setting the stroke length or by changing the pump speed via a frequency converter.

Dosing pumps are mainly used in processes or systems where a precise amount of liquid is required, for example in the chemical or petroleum industries. They can also be used to pump gaseous or even radioactive substances.

Submersible pumps – the salvation of containers and tanks

These types of pumps are submersible in the liquid to be pumped and are used in construction, commercial, domestic, municipal, industrial and storm water systems, for pumping borehole or rainwater, sewage, industrial or food waste, chemicals and corrosive fluids.

Submersible pumps are available in a variety of sizes and impeller types, depending on the viscosity of the liquid and the type, size and concentration of the solids pumped with the liquid. They are usually mounted on top and inside tanks or containers.

Pump selection and maintenance

It is quite difficult to choose the right one from the wide range of industrial pumps. To start the process, you need to decide which pump principle you need. Centrifugal or dynamic pumps cannot pump viscous liquids with a density exceeding 1800 kg/m³, while the chemical aggressiveness, particle size and concentration of the liquid to be pumped are important for positive displacement pumps. You can always consult the experts – the Axioma Service team not only supplies and repairs all types of industrial pumps, but also helps you to find the best solution for each customer’s individual needs.

Once you have installed a new industrial pump, maintenance should not be overlooked. A regular maintenance plan is important to prolong the life of the pump, maintain its efficiency and improve the reliability of the equipment. In this way, common faults such as leakage or extraneous noises can be avoided or easily solved.

Axioma servisas represents well-known manufacturers of industrial pumps such as:

Also offers the following services related to pumps and other rotating equipment:

- Comprehensive repair, maintenance and refurbishment of pumps and rotating equipment

- Pump diagnostics, fault prevention

- Centring of plant shafts

- Balancing of rotating parts of equipment

- Coating of internal surfaces of pumps, impellers and other elements with metal ceramics

- Upgrading of sealing assemblies

- Maintenance and renewal of bearings and bearing assemblies

- Turning, milling and other metal work, production of parts

Axioma servisas is an authorised service partner for GRUNDFOS, Apex Pumps and Alfa Laval pumps.

Do you have any questions regarding industrial pumps, their selection or maintenance? Contact our team at +370 699 63364 or by email orders@axs.eu.