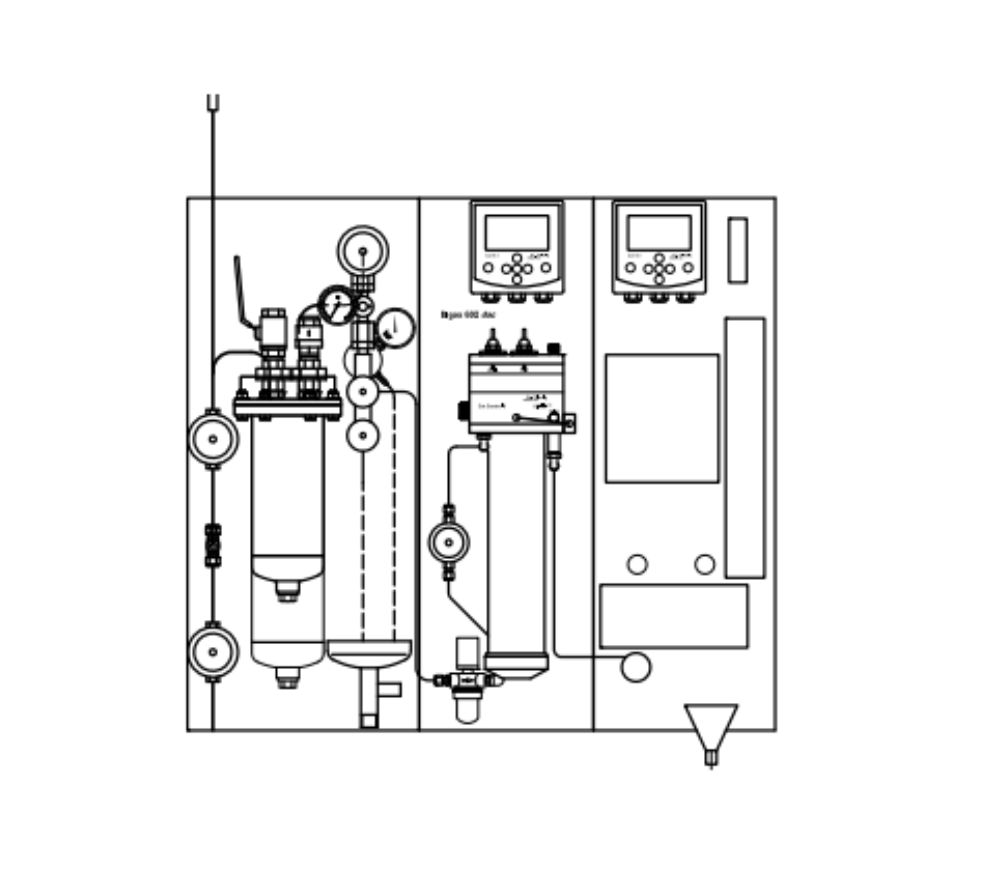

KNICK automatic cleaning and calibration system Unical 9000 ensures an ideal automatic pH measurement process. It consists of a Protos controller, a Memosens digital sensor, a Ceramat or SensoGate pneumatic fitting and a controller.

KNICK Unical 9000 automatic cleaning and calibration system:

- Enables highly accurate measurements even under challenging process conditions such as high pressure, high temperature or high impurity levels

- Can be installed close to the process in a hazardous area

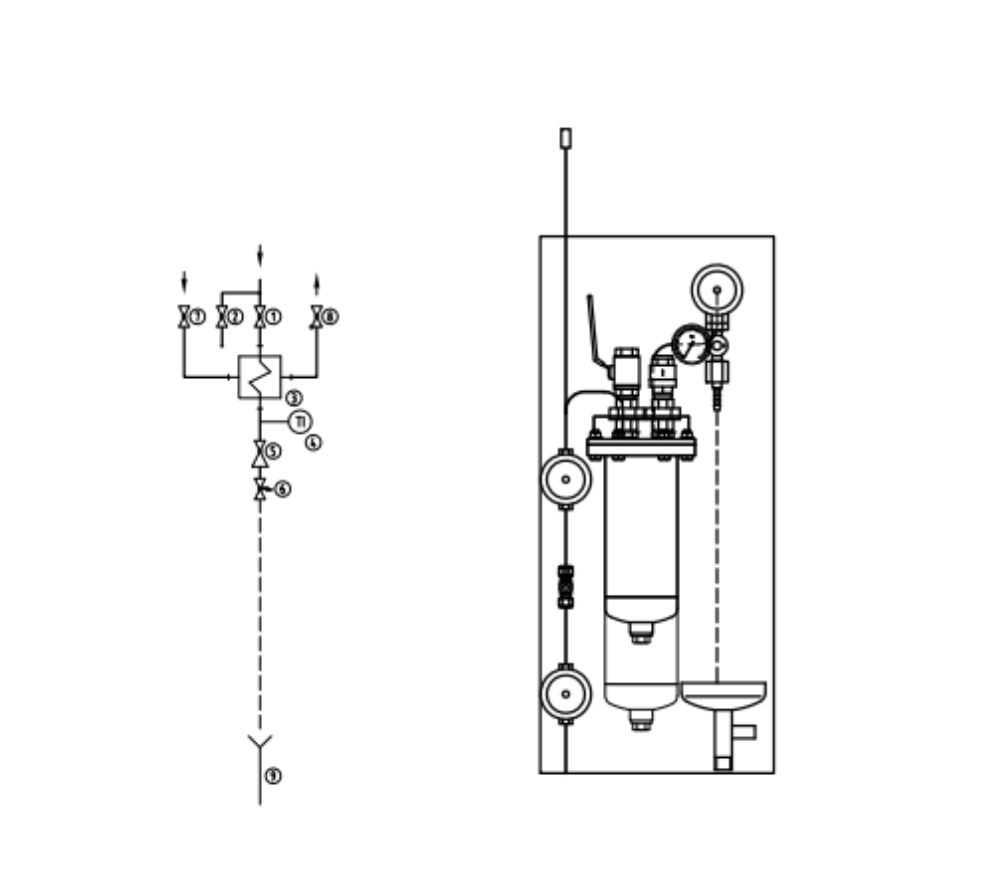

- Allows the process not to be interrupted because the sensoris not removable for calibration. Measurements in the pressure vessel or in the main pipe can be made without problems

Low maintenance

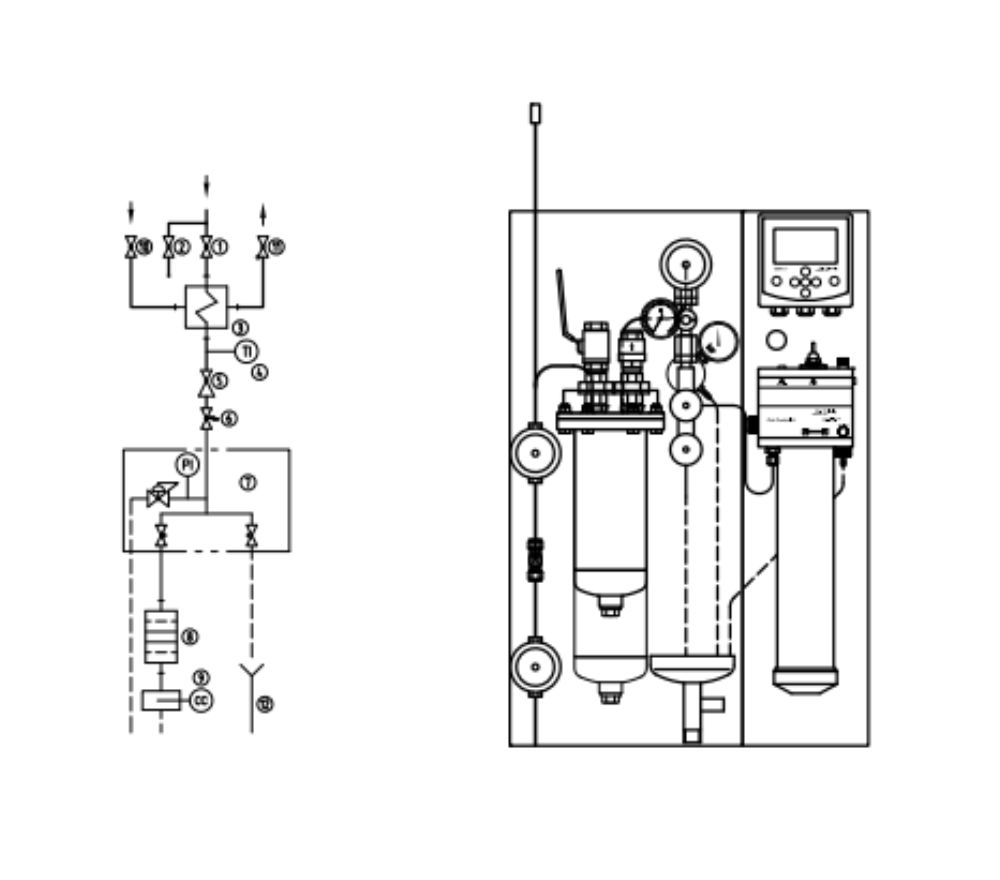

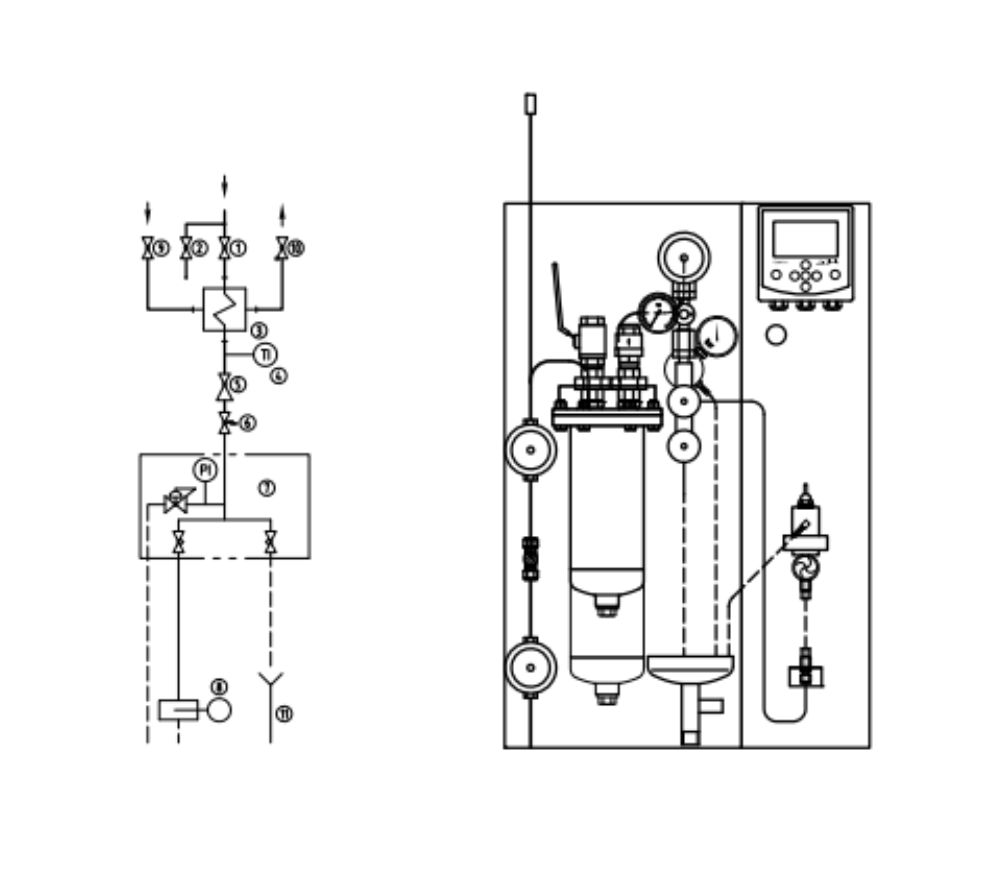

Fully automatic calibration of the sensor at user-defined intervals is carried out without interrupting the process. Two buffer solutions are automatically pumped into the calibration chamber. All you need to do is fill them in.

Lower costs

Low-wear, low-maintenance and ultra-low-cost devices.

Long sensor lifetime in complex processes

When measuring in aggressive media or at high process temperatures, the sensor is located in the calibration chamber and is only briefly moved into the measurement process. This method significantly increases the lifetime of the sensor.

Safe and simple measurement even in heavily contaminated media

Cleaning and rinsing of the sensor is carried out at user-defined intervals. The cleaning solution and water are automatically pumped into the calibration chamber. The sensor does not need to be manually removed and cleaned.

The difference between calibration and adjustment

This allows you to check the sensor data without stopping the process. The adjustment is only made when the deviation of the calibration values has been determined. Small deviations of continuously measured values are omitted.

Universal adaptation to retractable fittings

The automatic structure of the Unical system allows the use of any retractable fittings. Optimum functionality is achieved using Ceramat or SensoGate fittings.